Tool plates, type plates, inventory plates

We manufacture plates made of plastic, aluminium, brass & stainless steel for you.

Contact us!

Tool Labels

Tool labels for individual identification of tools. Produced according to your requests using plastic, aluminium or brass.

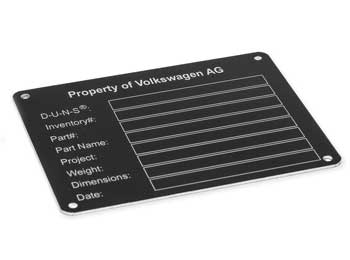

Type Plates

We offer the right sign to identify your machines and devices. Size, shape and material can be individually determined.

Asset Tags

Professional and permanent asset identification. We offer the appropriate signs as blank or with our number range, according to your requirement.